Make a solar cell in your kitchen

A solar cell is a device for converting energy from

the sun into electricity. The high-efficiency solar

cells you can buy at Radio Shack and other stores are

made from highly processed silicon, and require huge

factories, high temperatures, vacuum equipment, and

lots of money.

If we are willing to sacrifice efficiency for the ability

to make our own solar cells in the kitchen out of materials

from the neighborhood hardware store, we can demonstrate

a working solar cell in about an hour.

Our solar cell is made from

cuprous oxide instead of

silicon. Cuprous oxide is one of the first materials known

to display the

photoelectric effect, in which light

causes electricity to flow in a material.

Thinking about how to explain the photoelectric effect is

what led Albert Einstein to the Nobel prize for physics,

and to the theory of relativity.

Materials you will need

The solar cell is made from these materials:

- A sheet of copper flashing from the hardware store.

This normally costs about $5.00 per square foot.

We will need about half a square foot.

- Two alligator clip leads.

- A sensitive micro-ammeter that can read currents

between 10 and 50 microamperes. Radio Shack sells

small LCD multimeters that will do, but I used a

small surplus meter with a needle.

- An electric stove. My kitchen stove is gas, so I bought

a small one-burner electric hotplate for about $25. The

little 700 watt burners probably won't work -- mine is

1100 watts, so the burner gets red hot.

- A large clear plastic bottle off of which you can cut the top.

I used a 2 liter spring water bottle. A large mouth glass

jar will also work.

- Table salt. We will want a couple tablespoons of salt.

- Tap water.

- Sand paper or a wire brush on an electric drill.

- Sheet metal shears for cutting the copper sheet.

How to build the solar cell

My burner looks like this:

The first step is to cut a piece of the copper sheeting

that is about the size of the burner on the stove. Wash your

hands so they don't have any grease or oil on them. Then

wash the copper sheet with soap or cleanser to get any oil

or grease off of it.

Use the sandpaper or wire brush to thoroughly clean the copper

sheeting, so that any sulphide or other light corrosion is

removed.

Next, place the cleaned and dried copper sheet on the burner

and turn the burner to its highest setting.

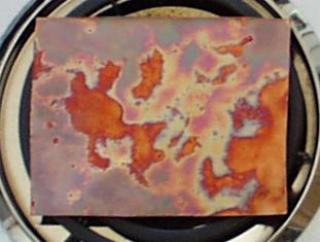

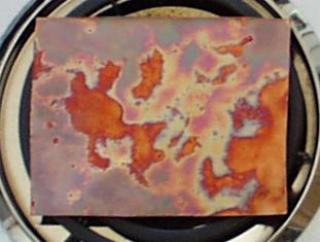

As the copper starts to heat up, you will see beautiful oxidation

patterns begin to form. Oranges, purples, and reds will cover the

copper.

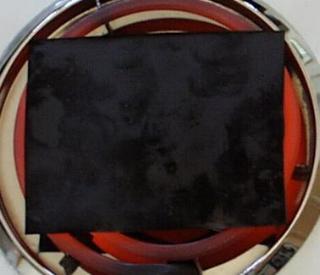

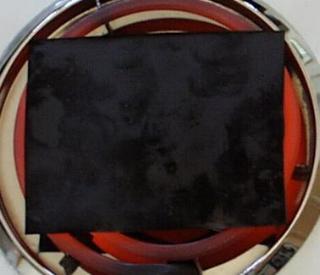

As the copper gets hotter, the colors are replaced with a black

coating of

cupric oxide. This is

not the oxide

we want, but it will flake off later, showing the reds, oranges,

pinks, and purples of the cuprous oxide layer underneath.

The last bits of color disappear as the burner starts to glow red.

When the burner is glowing red-hot, the sheet of copper will be

coated with a black cupric oxide coat. Let it cook for a half

an hour, so the black coating will be thick. This is important,

since a thick coating will flake off nicely, while a thin coat

will stay stuck to the copper.

After the half hour of cooking, turn off the burner.

Leave the hot copper on the burner to cool slowly.

If you cool it too quickly, the black oxide will stay

stuck to the copper.

As the copper cools, it shrinks.

The black cupric oxide also shrinks.

But they shrink at different rates, which makes

the black cupric oxide flake off.

The little black flakes pop off the copper with

enough force to make them fly a few inches. This

means a little more cleaning effort around the stove,

but it is fun to watch.

When the copper has cooled to room temperature (this takes about

20 minutes), most of the black oxide will be gone. A light scrubbing

with your hands under running water will remove most of the small

bits. Resist the temptation to remove all of the black spots by

hard scrubbing or by flexing the soft copper. This might damage

the delicate red cuprous oxide layer we need to make to solar cell work.

The rest of the assembly is very simple and quick.

Cut another sheet of copper about the same size as the first one.

Bend both pieces gently, so they will fit into the plastic bottle

or jar without touching one another. The cuprous oxide coating

that was facing up on the burner is usually the best side to face

outwards in the jar, because it has the smoothest, cleanest surface.

Attach the two alligator clip leads, one to the new copper plate,

and one to the cuprous oxide coated plate. Connect the lead from

the clean copper plate to the positive terminal of the meter.

Connect the lead from the cuprous oxide plate to the negative

terminal of the meter.

Now mix a couple tablespoons of salt into some hot tap water.

Stir the saltwater until all the salt is dissolved.

Then carefully pour the saltwater into the jar, being careful not

to get the clip leads wet. The saltwater should not completely

cover the plates -- you should leave about an inch of plate

above the water, so you can move the solar cell around without

getting the clip leads wet.

The photo above shows the solar cell in my shadow as I took

the picture. Notice that the meter is reading about 6 microamps

of current.

The solar cell is a battery, even in the dark, and will usually

show a few microamps of current.

The above photo shows the solar cell in the sunshine.

Notice that the meter has jumped up to about 33 microamps

of current. Sometimes it will go over 50 microamps, swinging

the needle all the way over to the right.

How does it do that?

Cuprous oxide is a type of material called a

semiconductor.

A semiconductor is in between a conductor, where electricity can

flow freely, and an insulator, where electrons are bound tightly

to their atoms and do not flow freely.

In a semiconductor, there is a gap, called a

bandgap between

the electrons that are bound tightly to the atom, and the electrons

that are farther from the atom, which can move freely and conduct

electricity.

Electrons cannot stay inside the bandgap. An electron cannot gain

just a little bit of energy and move away from the atom's nucleus

into the bandgap. An electron must gain enough energy to move

farther away from the nucleus, outside of the bandgap.

Similarly, an electron outside the bandgap cannot lose a little

bit of energy and fall just a little bit closer to the nucleus.

It must lose enough energy to fall past the bandgap into the

area where electrons are allowed.

When sunlight hits the electrons in the cuprous oxide, some of the

electrons gain enough energy from the sunlight to jump past the bandgap

and become free to conduct electricity.

The free electrons move into the saltwater, then into the clean copper plate,

into the wire, through the meter, and back to the cuprous oxide plate.

As the electrons move through the meter, they perform the work needed to

move the needle. When a shadow falls on the solar cell, fewer electrons

move through the meter, and the needle dips back down.